The Unsung Heroes Behind Clean Air: A Field Note on Filter Accessories

I’ve toured enough filtration plants to know the story: great media is only half the battle. The rest comes down to the humble, hard-working parts that hold everything together—like filters accessories. From PU glues to end caps and wire mesh, it’s the kit that determines whether your element survives a brutal service cycle or fails at the first gasket pinch. The team in Hebei—No.580 Gongnong Road, Shijiazhuang City 050000, China—has been quietly standardizing quality while keeping customization flexible. Honestly, that mix is rare.

Where the market is heading

Demand has shifted to one-stop procurement and tighter QA traceability. Buyers want modular, low-VOC adhesives, REACH/RoHS-safe elastomers, and frames that don’t rust after a single winter. There’s also a push for UL 94-compliant plastics in HVAC and EN 1822-grade sealing in cleanrooms. Many customers say they’re done juggling five vendors for gaskets, caps, and meshes—so a consolidated line of filters accessories is winning on total cost, not just unit price.

Core components and indicative specs

| Component | Material | Temp Rating | Typical Size | Shelf/Service Life | Notes |

|---|---|---|---|---|---|

| PU Glue (potting) | Polyol/MDI systems | ≈ -30 to 100°C | 1:1–1:5 mix | 12 months (sealed) | Low VOC options; real-world use may vary |

| End Caps | Galvanized steel, Al, PP | Up to 120°C | Custom OD/ID | 10+ years | Anti-corrosion coating available |

| Gaskets | EPDM/NBR/Silicone | -40 to 200°C | 3–20 mm | 3–5 years | Compression set ≤18% (typ.) |

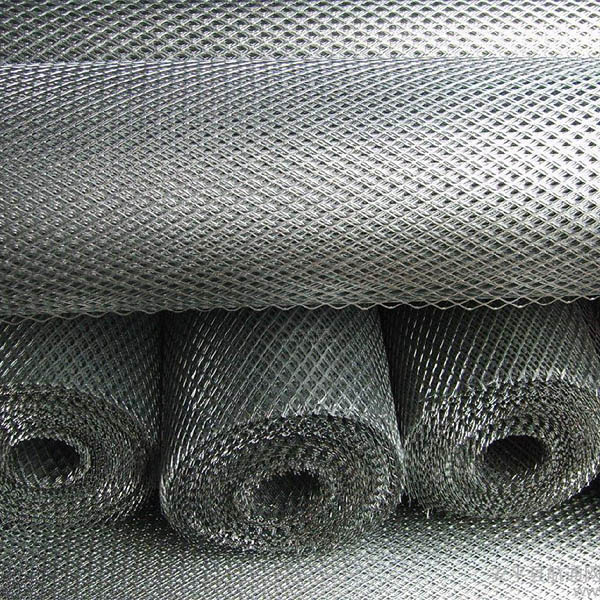

| Wire Mesh | SS304/316, GI | Up to 400°C | 10–80 mesh | NA | ASTM B117 salt spray tested |

Process and quality flow (quick version)

Materials arrive with COA. PU systems are vacuum-degassed, metered, and potted; curing typically 50–70°C for 30–120 min. End caps are stamped or injection-molded; frames laser-cut or roll-formed. Tests include durometer (Shore A), tensile (ASTM D412), adhesion (ASTM D3359), salt spray (ASTM B117, 72–240 h). Finished elements later qualify to ISO 16890 or EN 1822 when applicable; automotive lines reference ISO 5011. It’s not glamorous work, but it’s where failures are prevented.

Where they’re used (and why it matters)

- HVAC and cleanrooms: leak-proof seals for ISO 16890/EN 1822 grades.

- Automotive intake/cabin: ISO 5011 consistency, faster line changeovers.

- Dust collection and paint booths: durable caps and meshes reduce downtime.

- Food, pharma, and compressor air: silicone gaskets, low-odor adhesives.

Benefits? Lower pressure drop drift, fewer adhesive failures, and easier assembly. In practice, filters accessories make or break field performance.

Vendor snapshot (what buyers compare)

| Vendor | Lead Time | Certifications | Customization | QA/Traceability | Price Index |

|---|---|---|---|---|---|

| Anya Filter Media (Hebei) | 7–20 days (around) | ISO 9001, RoHS/REACH docs | Caps, molds, logos, cuts | Batch IDs, test reports | Baseline 1.0 |

| Brand B (EU) | 15–30 days | ISO 9001/14001 | Moderate | Strong | 1.4–1.7 |

| Trader C (APAC) | 10–25 days | Basic | Limited | Mixed | 0.9–1.1 |

Customization, tests, and what users report

Options: embossed end caps, private molds, EPDM vs. silicone swaps, pre-cut mesh, and kit-packed filters accessories. Typical data points I saw: PU peel strength ≈2.1 N/mm on polyester media; gasket compression set ≤18% at 70°C/22 h; mesh passed 120 h salt spray. Compliance packs: ISO 9001, UL 94 (on request), REACH/RoHS statements, and MSDS for chemicals. Feedback? “Fewer leaks after transport,” one HVAC OEM told me—simple but huge.

Three quick case notes

- MENA HVAC line: switch to silicone gaskets cut leak rate to

- EU dust collection OEM: galvanized caps with better coating survived 240 h salt spray, zero blistering.

- Auto Tier-2, EE: PU potting tweak reduced scrap by 6.2% across two quarters—small tweak, big savings.

Bottom line: if you’re standardizing bills of materials and want fewer surprises in the field, tighten up your filters accessories. It’s not flashy, but it’s the reliability layer your media deserves.

Authoritative citations

- ISO 16890: Air filters for general ventilation.

- EN 1822-1: High efficiency air filters (EPA, HEPA, ULPA).

- ISO 5011: Inlet air cleaning equipment for internal combustion engines.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- UL 94: Tests for Flammability of Plastic Materials.

- EU REACH Regulation (EC) No 1907/2006.

- RoHS Directive 2011/65/EU and amendments.

Post time: Oct-01-2025