Understanding Air Filter Paper Material: Essential for Modern Filtration

In industrial and commercial environments, the quality of filtered air directly impacts operational efficiency, equipment longevity, and public health. Central to achieving superior air filtration performance is the selection and engineering of the core filtration medium: air filter paper material. This advanced material is meticulously designed to capture particulates, allergens, and contaminants, ensuring clean air delivery across a myriad of applications, from HVAC systems to sophisticated industrial processes. Its efficacy is paramount, serving as the frontline defense against airborne pollutants.

This comprehensive guide delves into the intricacies of air filter paper, exploring its manufacturing, technical specifications, diverse applications, and the competitive advantages it offers to B2B decision-makers and engineers. We aim to provide an authoritative resource, grounded in technical expertise and real-world application, to inform strategic procurement and system design.

Industry Trends and Market Dynamics in Air Filtration

The global air filtration market is experiencing robust growth, driven by escalating concerns over air quality, stringent environmental regulations, and increasing industrialization. Key trends influencing the demand for advanced air filter paper material include:

- Rising Demand for High-Efficiency Filtration: The need for filters meeting HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) standards is increasing, particularly in medical, pharmaceutical, and cleanroom environments, pushing innovation in hepa filter paper roll technology.

- Energy Efficiency: Manufacturers are prioritizing filter media that offer lower pressure drop without compromising filtration efficiency. This translates to reduced energy consumption for HVAC systems and industrial machinery, directly impacting operational costs.

- Sustainability and Eco-Friendly Materials: There's a growing emphasis on recyclable, biodegradable, or long-lasting filter materials to minimize environmental impact.

- Smart Filtration Systems: Integration of sensors and IoT for real-time monitoring of filter performance and lifespan is becoming more common, necessitating consistent and predictable media performance.

- Specific Contaminant Removal: Beyond particulates, filter media are being developed to target specific pollutants like volatile organic compounds (VOCs) and chemical warfare agents, often incorporating activated carbon layers or specialized fiber treatments.

The market for filter media, including ac filter paper, is projected to reach approximately $13.5 billion by 2027, growing at a CAGR of around 6.5%. This expansion underscores the critical role of innovative and high-performance filter media solutions.

The Manufacturing Process of Air Filter Paper Material

The creation of high-performance air filter paper material is a sophisticated multi-stage process, demanding precision and adherence to strict quality controls. It primarily involves the wet-laid nonwoven technique, similar to papermaking, but with specialized fibers and binders.

Key Materials:

- Glass Fibers: Typically micro-glass fibers (borosilicate), ranging from sub-micron to a few microns in diameter, forming a dense, intricate web for high filtration efficiency.

- Synthetic Fibers: Polypropylene (PP), polyethylene terephthalate (PET), or bicomponent fibers offer enhanced strength, moisture resistance, and often a lower pressure drop.

- Cellulose Fibers: Used in some lower-grade applications or as a base layer for mechanical support, though less common for high-efficiency filters.

- Binders: Acrylic resins, styrene-butadiene rubber (SBR), or other polymers are used to bond the fibers, providing structural integrity, rigidity, and resistance to moisture and chemicals. These binders are critical for maintaining pore structure and strength during pleating and operation.

Manufacturing Process Steps (Schematic):

- Fiber Preparation: Raw fibers are dispersed in water to create a uniform slurry. This step ensures consistent fiber distribution in the final product.

- Web Formation (Wet-laid Process): The slurry is fed onto a moving screen (Fourdrinier or inclined wire), where water is drained, leaving a uniform mat of fibers. Precision control of flow rate and suction is vital for consistent basis weight and porosity.

- Binder Impregnation: The wet fiber web passes through a bath containing a binder solution. The binder saturates the web, and excess is removed. This step is crucial for the mechanical strength and durability of the filter paper.

- Drying and Curing: The impregnated web enters drying ovens where water is evaporated, and the binder is cured, cross-linking the fibers. Temperature and time are precisely controlled to achieve optimal strength and filter media characteristics.

- Calendering (Optional): The dried paper may pass through heated rollers to achieve desired thickness, smoothness, and density, influencing air permeability and tensile strength.

- Quality Control & Testing: Throughout the process, and especially at the end, the material undergoes rigorous testing.

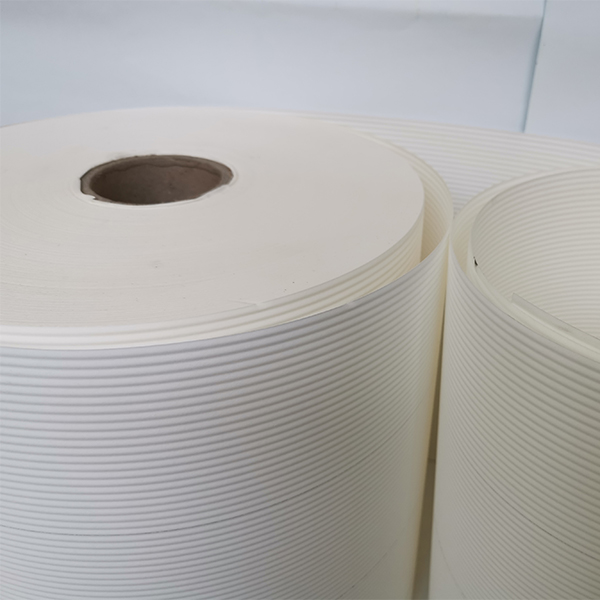

- Slitting and Winding: The finished filter paper is slit into specified widths and wound into large hepa filter paper roll or smaller rolls for shipment.

Testing Standards: Finished filter media conform to international standards such as ISO 16890 (ePM1, ePM2.5, ePM10), EN 1822 (HEPA and ULPA filters), and ASHRAE 52.2 (MERV ratings) for HVAC applications. These standards define efficiency, pressure drop, and dust holding capacity, ensuring reliable performance in industries like petrochemical, metallurgy, and water supply & drainage.

Technical Specifications and Performance Parameters

The performance of air filter paper material is characterized by several critical parameters. Understanding these is crucial for selecting the appropriate media for specific applications.

- Basis Weight (g/m²): Indicates the mass per unit area, affecting material density and potentially pressure drop.

- Thickness (mm): Influences pleatability and the overall depth of the filter bed.

- Air Permeability (L/m²/s or cfm): Measures the volume of air that passes through a given area of the material at a specific pressure drop. Higher permeability generally means lower initial pressure drop.

- Filtration Efficiency (%): The ability of the media to remove particles of a specific size. This is often expressed via MERV, ePM, or HEPA classifications. For instance, HEPA H13 media achieve 99.95% efficiency for particles at MPPS (Most Penetrating Particle Size).

- Pressure Drop (Pa or in. w.g.): The resistance to airflow across the filter media. A lower pressure drop reduces energy consumption.

- Dust Holding Capacity (DHC) (g/m²): The amount of dust the filter media can hold before reaching a specified terminal pressure drop. A higher DHC extends service life.

- Tensile Strength (N/15mm): The material's resistance to tearing or breaking, critical for withstanding the pleating process and operational stresses.

- Burst Strength (kPa): The pressure required to rupture the media, indicating durability.

- Heat Resistance (°C): The maximum continuous operating temperature the media can withstand without degradation.

- Moisture Resistance: The ability to maintain performance and structural integrity in humid environments.

Typical Product Specification Table (Example for HEPA Grade Filter Media)

| Parameter | Unit | Value Range | Test Standard |

|---|---|---|---|

| Basis Weight | g/m² | 60 - 150 | ISO 536 |

| Thickness | mm | 0.25 - 0.80 | ISO 534 |

| Air Permeability (200 Pa) | L/m²/s | 50 - 200 | ISO 9237 |

| Filtration Efficiency (MPPS) | % | ≥ 99.95 (H13) | EN 1822-3 |

| Initial Pressure Drop (at rated flow) | Pa | ≤ 50 (at 0.05 m/s) | EN 1822-3 |

| Tensile Strength (MD/CD) | N/15mm | ≥ 25 / ≥ 10 | ISO 1924-2 |

| Maximum Operating Temp. | °C | 250 | Internal Testing |

These parameters are meticulously controlled during manufacturing to ensure the resulting filter media meets the stringent requirements of its intended application, whether it's for critical cleanroom filtration or general HVAC use.

Types and Classifications: HEPA and AC Filter Paper

The versatility of air filter paper material is evident in its various classifications, each designed for specific performance criteria. Two prominent categories often discussed are hepa filter paper roll and ac filter paper.

HEPA Filter Paper Roll: Uncompromising Purity

HEPA (High-Efficiency Particulate Air) filter media are engineered for the most demanding applications where particle removal down to sub-micron levels is critical. Typically made from micro-glass fibers and specialty binders, these media achieve efficiencies of 99.97% or higher for particles 0.3 microns in size (MPPS). They are essential for:

- Cleanrooms (ISO Class 1-8)

- Pharmaceutical manufacturing

- Hospitals and healthcare facilities (operating theaters, isolation rooms)

- Micro-electronics fabrication

- Nuclear applications

The manufacturing of a hepa filter paper roll requires extremely precise fiber control and impregnation to maintain a uniform pore structure, minimizing pressure drop while maximizing efficiency and dust holding capacity.

AC Filter Paper: Versatility for HVAC Systems

AC (Air Conditioning) filter paper refers to a broad category of filter media used in residential, commercial, and industrial HVAC systems. These filters are classified by MERV (Minimum Efficiency Reporting Value) ratings according to ASHRAE Standard 52.2 or by ePM classes (ePM1, ePM2.5, ePM10) according to ISO 16890. Materials can range from synthetic fibers to cellulose blends, often impregnated with resins to enhance strength and moisture resistance.

- MERV 8-10: Good for general filtration, capturing pollen, dust mites, and mold spores.

- MERV 11-13: Enhanced filtration for fine dust, pet dander, and smog, suitable for office buildings and schools.

- MERV 14-16: High-efficiency commercial filters, often used in hospitals (non-critical areas) and industrial settings.

The selection of ac filter paper balances efficiency, pressure drop, and cost, ensuring optimal indoor air quality without excessively burdening HVAC system energy consumption. These media often come in large rolls, ready for pleating and assembly into various filter configurations.

Technical Advantages of High-Performance Air Filter Paper Material

Investing in advanced air filter paper material offers substantial technical and economic advantages for businesses. These benefits extend beyond simple particle capture, impacting overall system performance and operational costs.

- Superior Filtration Efficiency: Modern filter media can achieve very high efficiencies (e.g., ePM1 > 80% or HEPA H14 > 99.995%), effectively capturing ultrafine particles, bacteria, and viruses, thereby protecting sensitive equipment and human health.

- Reduced Energy Consumption: Engineered with low initial pressure drop, these materials minimize the load on fans and blowers in HVAC systems and industrial processes. A 10% reduction in pressure drop can lead to significant energy savings, often justifying the investment in premium filter media. This is a critical factor for large-scale operations.

- Extended Service Life and Dust Holding Capacity: Advanced filter paper designs, often featuring graded fiber densities or unique pleating patterns, provide higher dust holding capacities. This extends the lifespan of filters, reducing replacement frequency, maintenance labor, and waste disposal costs.

- Enhanced Structural Integrity: Resin-impregnated media offers superior wet strength, burst strength, and dimensional stability, ensuring the filter maintains its performance even under fluctuating humidity or high airflow conditions. This prevents media breakdown and fiber shedding.

- Corrosion and Chemical Resistance: For specific industrial applications, specialized filter papers are treated or manufactured with fibers resistant to corrosive gases, acids, or alkalis, ensuring reliable performance in harsh chemical environments.

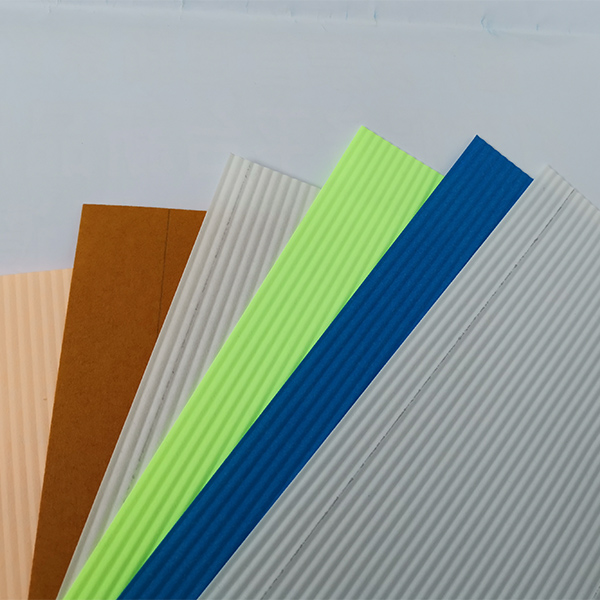

- Versatility in Application: Available in a wide range of efficiencies, thicknesses, and roll widths, filter paper can be customized for diverse filter types, including panel filters, bag filters, rigid cell filters, and mini-pleat filters.

These advantages collectively contribute to a lower total cost of ownership (TCO) and improved operational reliability for critical infrastructure. For example, by optimizing filtration, a petrochemical plant can extend the life of sensitive catalysts, directly translating to substantial cost savings and increased uptime.

Application Scenarios and Target Industries

The broad utility of air filter paper material spans across nearly every sector requiring clean air, process protection, or environmental compliance. Its adaptability makes it indispensable in numerous industries:

- HVAC Systems (Commercial & Industrial): From large office complexes and shopping malls to manufacturing plants and data centers, ac filter paper is vital for maintaining indoor air quality, protecting coils, and ensuring efficient operation of heating, ventilation, and air conditioning units.

- Healthcare & Pharmaceuticals: HEPA and ULPA grade air filter paper material is critical in operating rooms, isolation wards, cleanrooms for drug manufacturing, and biological safety cabinets to prevent cross-contamination and protect patients and products from airborne pathogens.

- Automotive Industry: Used in engine air filters to protect engines from abrasive dust, cabin air filters to ensure passenger comfort and health, and in paint spray booths to prevent defects.

- Food & Beverage Processing: High-efficiency filters prevent contamination of food products by airborne microorganisms and particles, adhering to strict hygiene standards.

- Electronics & Semiconductor Manufacturing: Ultra-fine filtration using hepa filter paper roll is essential in cleanrooms to prevent even microscopic particles from damaging sensitive electronic components during production.

- Industrial & Manufacturing: Dust collection systems, gas turbines, compressors, and industrial ovens all rely on specialized filter media to protect machinery, improve worker safety, and comply with emissions regulations. Examples include protecting gas turbine intakes from fine dust in power generation or ensuring clean air for pneumatic tools in manufacturing.

- Mining & Heavy Equipment: Robust filter media are used in heavy-duty equipment to protect engines and hydraulics from extreme dust and particulate loads, extending equipment life in harsh operating environments.

Each application demands specific characteristics from the filter paper, whether it's high temperature resistance, chemical inertness, or exceptionally high filtration efficiency. Suppliers of filter media must offer a versatile product portfolio to meet these varied industry requirements effectively.

Vendor Comparison and Value Proposition

Choosing the right supplier for air filter paper material is a strategic decision that impacts product quality, operational costs, and supply chain reliability. While numerous vendors offer filter media, differentiation lies in several key areas:

- Technical Expertise and R&D: Leading vendors invest heavily in research and development to create innovative media with improved efficiency, lower pressure drop, and enhanced durability. This includes advanced fiber technologies and binder chemistries.

- Quality Assurance & Certifications: Adherence to international standards (ISO 9001, ISO 16890, EN 1822) and robust internal QC processes are non-negotiable for consistent product performance. Certifications like ISO 14001 also demonstrate environmental responsibility.

- Customization Capabilities: The ability to tailor media specifications—such as basis weight, thickness, permeability, and chemical treatments—to specific customer requirements is a significant differentiator.

- Supply Chain Reliability: A vendor with a strong global presence, efficient logistics, and redundant manufacturing capabilities ensures timely delivery and mitigates supply risks.

- Technical Support and Collaboration: A partner that offers expert technical support, application engineering assistance, and collaborative problem-solving adds immense value.

- Cost-Effectiveness (Total Cost of Ownership): While initial price is a factor, the long-term TCO (including energy savings, extended filter life, and reduced maintenance) is a more accurate measure of value.

Product Comparison: Synthetic vs. Glass Microfiber Media for HEPA Filters

| Feature | Glass Microfiber Media | Synthetic Media (e.g., PP/PET) |

|---|---|---|

| Efficiency Class | H10 - U17 (EN 1822) | F7 - H13 (EN 1822) / MERV 13 - 16 |

| Fiber Material | Borosilicate micro-glass fibers | Polypropylene, Polyester, Bicomponent fibers |

| Primary Filtration Mechanism | Diffusion & Interception | Interception & Impaction |

| Pressure Drop | Generally very low for given efficiency | Can be optimized for low pressure drop, often slightly higher than glass for same efficiency |

| Moisture Resistance | Excellent with proper binder | Naturally hydrophobic, excellent |

| Chemical Resistance | Good, depending on binder | Very good for common chemicals |

| Thermal Stability | High (up to 300°C with specialty binders) | Moderate (up to 120-150°C) |

| Cost | Higher for very high efficiencies | Generally more cost-effective for mid-range efficiencies |

| Applications | Cleanrooms, pharma, nuclear, critical process air | General HVAC, automotive, pre-filters for HEPA |

This comparison highlights that the optimal choice of air filter paper material depends heavily on the specific application's requirements for efficiency, environmental conditions, and budget.

Customized Solutions for Air Filter Paper Material

Recognizing that standard products may not always meet the unique demands of specialized applications, leading manufacturers offer extensive customization capabilities for air filter paper material. This tailored approach ensures optimal performance and efficiency for bespoke filtration systems.

Key Areas of Customization:

- Efficiency and Pressure Drop Profiles: Adjusting fiber blend ratios, basis weight, and fiber diameter allows for fine-tuning the balance between filtration efficiency (e.g., specific MERV or ePM ratings) and pressure drop to meet precise energy consumption targets.

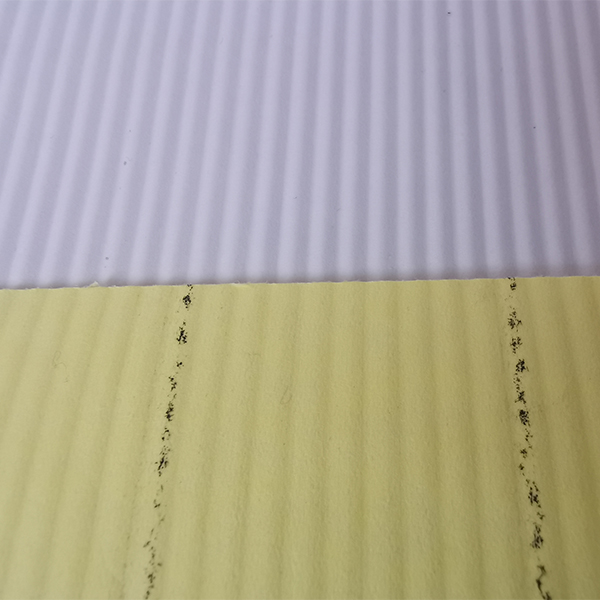

- Chemical Treatments and Coatings:

- Hydrophobic/Hydrophilic Treatments: To enhance performance in high humidity or ensure water drainage.

- Antimicrobial Agents: For applications where bio-growth prevention is critical (e.g., healthcare, food processing).

- Flame Retardants: To meet specific fire safety standards in demanding industrial environments.

- Odor Adsorption: Integration of activated carbon for combined particulate and gaseous contaminant removal, crucial for ac filter paper in sensitive indoor environments.

- Mechanical Strength and Durability: Modifying binder types and concentrations or incorporating specific reinforcing fibers can enhance tensile strength, burst strength, and abrasion resistance, vital for dynamic or harsh operating conditions.

- Thermal Stability: Using high-temperature resistant glass fibers and specialized binders enables filter media to withstand elevated operating temperatures, essential for industrial ovens or exhaust systems.

- Roll Dimensions and Core Sizes: Media can be supplied in custom widths and roll diameters to fit specific manufacturing equipment and production lines, optimizing throughput for filter manufacturers.

Our engineering teams work closely with clients to define precise performance envelopes, conducting joint R&D and pilot testing to develop solutions that seamlessly integrate into their filter designs and end applications. This collaborative approach ensures that the bespoke air filter paper material delivers optimal performance and long-term reliability.

Application Case Studies

Real-world implementations demonstrate the tangible benefits of selecting high-quality air filter paper material.

Case Study 1: Data Center HVAC Optimization

A large data center operator faced significant energy costs due to high pressure drop across their MERV 13 ac filter paper. The existing media required frequent fan speed increases, leading to higher electricity consumption. Our team collaborated with their engineers to identify a new synthetic filter media with optimized fiber structure. This customized solution provided equivalent MERV 13 efficiency but with a 20% lower initial pressure drop. The implementation resulted in an estimated 15% reduction in fan energy consumption, translating to annual savings of over $50,000 and extended filter change-out intervals by 3 months, further reducing maintenance costs.

Case Study 2: Pharmaceutical Cleanroom Upgrade

A pharmaceutical manufacturer needed to upgrade their ISO Class 7 cleanroom to ISO Class 6 for a new product line requiring stricter environmental controls. Their existing HEPA filters, while efficient, exhibited inconsistent performance and were prone to slight media breakdown under high airflow, leading to micro-fiber shedding concerns. We supplied specialized hepa filter paper roll made from robust, high-purity micro-glass fibers with a chemically stable binder, specifically engineered for ultra-low shedding and consistent H14 efficiency. Post-implementation, particle counts consistently met ISO Class 6 standards, and the client reported zero media-related contamination incidents, significantly enhancing product safety and compliance.

Case Study 3: Industrial Dust Collection in Woodworking

A large-scale woodworking facility struggled with frequent clogging and short lifespan of dust collector filters due to the high volume and abrasive nature of wood dust. The existing filter media offered insufficient dust holding capacity. Our solution involved a heavy-duty, resin-impregnated air filter paper material designed for high dust loads and excellent pleat stability. This media, while maintaining efficient particle capture (ePM10), doubled the lifespan of their cartridge filters, reducing filter replacement frequency by 50% and minimizing production downtime, ultimately leading to substantial operational savings and improved air quality for workers.

Quality Assurance and Certifications

Authoritativeness in the filter media industry is built on rigorous quality control and adherence to international standards. Our commitment to excellence is reflected in our comprehensive quality management systems and adherence to global benchmarks.

Certifications and Compliance:

- ISO 9001: Our manufacturing facilities are certified to ISO 9001, ensuring a consistent quality management system across all operations, from raw material sourcing to final product inspection for all air filter paper material.

- EN 1822 & ISO 29463: Our HEPA and ULPA grade filter media are tested and certified to meet the stringent requirements of EN 1822 (for H10-U17 classifications) and ISO 29463, verifying their efficiency and pressure drop performance.

- ISO 16890 & ASHRAE 52.2: Our HVAC filter media (including ac filter paper) comply with ISO 16890 (ePM1, ePM2.5, ePM10) and ASHRAE 52.2 (MERV ratings), providing verifiable performance data for various particulate sizes.

- Internal Quality Control: Beyond external certifications, every batch of hepa filter paper roll and other media undergoes comprehensive internal testing for basis weight, thickness, air permeability, tensile strength, and efficiency using state-of-the-art laboratory equipment.

- Authoritative References: We routinely conduct third-party testing at accredited laboratories to validate our product claims and ensure unbiased performance assessments.

Our decade-long experience in serving leading HVAC manufacturers, cleanroom builders, and industrial filter producers speaks to our proven track record and commitment to delivering reliable, high-performance filter media solutions.

Ordering and Support: Your Trusted Partner

As a dedicated B2B supplier of air filter paper material, we understand the critical importance of reliable supply, transparent processes, and robust support. We are committed to fostering long-term partnerships built on trust and mutual success.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a standard order of hepa filter paper roll?

A: For standard specifications, our lead time typically ranges from 3 to 4 weeks, depending on order volume and current production schedules. Expedited options may be available upon request. Customized orders may require additional time for sample production and approval.

Q: How do you ensure the consistent quality of your air filter paper material?

A: We operate under an ISO 9001 certified quality management system. Every production batch undergoes comprehensive testing for critical parameters such as basis weight, thickness, air permeability, tensile strength, and filtration efficiency against relevant international standards (e.g., ISO 16890, EN 1822). Detailed Certificates of Analysis are provided with each shipment.

Q: Can your ac filter paper be customized for specific HVAC system requirements?

A: Absolutely. We offer extensive customization for our AC filter paper, including tailored efficiency ratings (MERV/ePM), pressure drop characteristics, flame retardancy, and specific roll dimensions. Our technical team works closely with clients to develop solutions that perfectly match their system's performance and operational requirements.

Lead Time & Fulfillment

We maintain a streamlined manufacturing and logistics process to ensure timely delivery of all orders. Standard lead times are communicated clearly at the time of quotation. For urgent requirements or large-volume contracts, we collaborate with clients to establish optimized production and inventory strategies, including buffer stock options, to guarantee supply continuity.

Warranty Commitments

Our air filter paper material is backed by a comprehensive warranty against manufacturing defects and for performance as per agreed-upon specifications. We stand by the quality and reliability of our products, ensuring that they meet or exceed industry standards for their intended applications. Specific warranty details are provided with each product agreement.

Customer Support and Technical Assistance

Our dedicated customer support and technical sales teams are available to assist with product selection, application engineering, technical troubleshooting, and order management. We provide expert guidance to help you choose the ideal filter media for your specific needs, optimizing performance and cost-efficiency. From initial inquiry to post-delivery support, we are committed to providing an unparalleled customer experience.

Conclusion

The strategic selection of air filter paper material is a cornerstone for achieving optimal air quality, protecting sensitive equipment, and ensuring operational efficiency across a vast array of industries. From the precision-engineered fibers of hepa filter paper roll crucial for pharmaceutical cleanrooms to the versatile performance of ac filter paper in commercial HVAC systems, the underlying technology continues to evolve, driven by demands for higher efficiency, lower energy consumption, and greater sustainability.

Partnering with a knowledgeable and experienced supplier capable of delivering customized, high-quality filter media is paramount. By understanding the intricate manufacturing processes, technical specifications, and real-world application advantages, B2B decision-makers can make informed choices that yield significant long-term benefits in performance, cost savings, and environmental compliance. Our commitment to innovation, quality, and customer support positions us as a trusted partner in navigating the complex landscape of advanced air filtration solutions.

References

- International Organization for Standardization (ISO). ISO 16890:2016, Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based on particulate matter (ePM).

- European Committee for Standardization (CEN). EN 1822-1:2019, High efficiency air filters (EPA, HEPA and ULPA) – Part 1: Classification, performance testing, marking.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ASHRAE Standard 52.2-2017, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- Research and Markets. "Air Filter Media Market - Global Outlook & Forecast 2022-2027." Published February 2022.

- ASTM International. ASTM D5034-09(2017), Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test).

Post time: Sep-02-2025