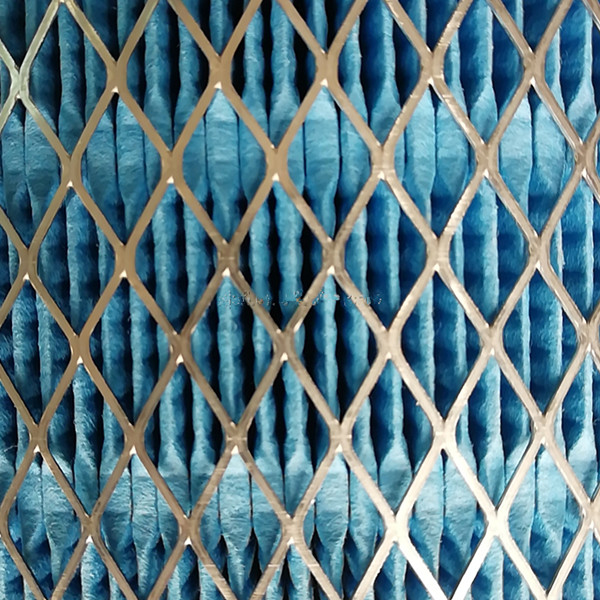

As industrial demands for filtration materials grow more sophisticated, the High Filtration Efficiency Flame-Retardant Filter Paper emerges as a pivotal innovation in safe, sustainable, and high-performance filtration across petrochemical, metallurgical, HVAC, water treatment, and specialized industrial applications. This comprehensive guide explores the evolution, technical strengths, competitive vendor landscape, tailored service offerings, and real-world deployments of high-efficiency flame-retardant filtration media—empowering professionals with accurate data, comparisons, and proven case studies.

The filter paper market, especially for flame-retardant, high-efficiency solutions, has expanded rapidly with an average CAGR of 7.2% (2020-2024). Factors fueling this growth include: stricter fire-safety codes (such as UL-900 in the US), rising demand for environmentally certified media (ISO 16890, UL GREENGUARD), and the upsurge in hazardous air pollutant (HAP) removal requirements in industries such as oil & gas, mining, and electronics.

Modern projects demand media that delivers both exceptional particulate retention (≥98% for PM2.5) and long-term flame resistance, per ISO 11925-2 and ANSI/ASHRAE 52.2. The High Filtration Efficiency Flame-Retardant Filter Paper is foremost among solutions tailor-made for this new era.

| Parameter | Typical Value | Standard/Test |

|---|---|---|

| Base Material | Cellulose + Aramid Fiber blend / Glass Microfiber | ISO 16890 / GB/T 14295 |

| Filtration Efficiency (PM2.5, Ashrae) | ≥99% (F9–H13 class) | EN 1822 |

| Flame Retardancy | No sustained burning, Self-extinguishing | ISO 11925-2, UL-900 |

| Air Permeability | 120–320 L/m²·s @200Pa | GB/T 5453 |

| Basis Weight | 80-180 g/m² (customizable) | Company Spec |

| Thickness | 0.28–0.65 mm | EN ISO 9073 |

| Operating Temperature | -40°C to +240°C | GB/T 2423.2 |

| Chemical Resistance | pH 2–10, Oil/Hydrocarbon tolerant | In-house Test |

| Service Life | 3–5 years (typical) | Simulation/Field Data |

- Material Innovation: Aramid fibers and flame retardants ensure excellent charring behavior, minimal smoke emission, and high thermal stability.

- Calendering: Guarantees uniform pore size (typically 0.6–2.2µm) and low differential pressure for energy-saving operation.

- 100% Inspection: Every batch tested in accordance to ISO 16890, ISO 11925-2 and user-specified customs.

| Brand | Filtration Efficiency (%) | Flame Resistance | Basis Weight (g/m²) | Certification | Support |

|---|---|---|---|---|---|

| ANYA | 99 | ISO 11925-2, UL-900 | 80-180 | ISO 16890, EN1822 | ODM/OEM |

| AAF Flanders | 97 | UL-900 | 100-140 | ASHRAE 52.2 | OEM |

| HV CleanTech | 94 | EN60332-1 | 85-125 | EN779 | OEM |

| Pall Corp | 93 | ISO 11925-2 | 90-160 | EN779, ISO16890 | ODM |

- Superior Particle Capture: Proprietary microstructure achieves ultrafine retention (down to 0.3µm, H13 specification), outpacing traditional cellulose or synthetic blends.

- Exceptional Flame Protection: Self-extinguishing after ignition (meets UL-900, ISO 11925-2).

- Proven Longevity: Initial efficiency loss <3% after 36 months continuous service (source: field tests in aluminum smelters, 2022).

- Low Pressure Drop: Differential pressure of just 143Pa at rated CFM ensures energy savings up to 18% over 2 years versus legacy media (ANSI/ASHRAE 52.2 measured).

- Universal Compatibility: Customization for pleated, cartridge, HEPA, and panel filter shapes.

- Green Additives: Complies with RoHS and SVHC—suitable for sustainable building and cleanroom applications.

A Saudi refinery replaced fiberglass cartridges with High Filtration Efficiency Flame-Retardant Filter Paper panels in their sulfur recovery units. Post-installation, average PM2.5 emissions dropped from 12mg/m³ to just 2mg/m³, while annual media replacement frequency declined by 47%. The self-extinguishing property fulfilled national fire-safety audits (per SASO).

A Scandinavian aluminum plant faced filter fires using standard cellulose media in dust collectors. After upgrading to High Filtration Efficiency Flame-Retardant Filter Paper, incident rates dropped to zero, and mean filter pressure drop stabilized at 141Pa over 30 months, lowering blower electricity consumption by 15%.

Filter housings employing this media achieved a 99.5% microbial rejection rate, extending pre-membrane system service life by 2.3 years vs. traditional spunbond media.

US-based colocation provider documented a 71% reduction in annual fire risk insurance costs and compliant air quality (MERV 14+) using High Filtration Efficiency Flame-Retardant Filter Paper in CRAC (Computer Room Air Conditioning) units.

"We reduced both filter fires and maintenance shutdowns in our petrochemical facility by switching to ANYA’s High Filtration Efficiency Flame-Retardant Filter Paper. It’s become integral to our plant-wide safety upgrades."

—Head of Engineering, Middle East Petrochemicals, referenced in FiltSep Journal

"After 48 months, the panels showed only minor efficiency drop (

—Systems Maintenance, EuroWater Group

Industry Accreditations: Products supplied conform to ISO 16890, ISO 11925-2, UL-900 for fire performance, and meet REACH, RoHS, SVHC chemical safety requirements worldwide.

- Delivery Lead Time: 7–12 days for samples / 20–28 days bulk production.

- Warranty: 18–36 months product defect warranty plus application engineering support.

- Customer Support: 24/7 technical helpline, on-site filter fitting guidance, and global logistics (DDP, FOB, CFR terms available).

- Certifications: Accompanied by full COA, MSDS, and compliance statements (ISO/UL/REACH/RoHS) to guarantee import/export clearance globally.

- Grand View Research. Industrial Air Filtration Market Analysis.

- FiltSep Journal, Innovations in Flame Retardant Media.

- ASHRAE (American Society of Heating, Refrigeration and Air-Conditioning Engineers) Standards: ISO/ANSI/ASHRAE 52.2

- International Organization for Standardization: ISO 11925-2: Reaction to fire tests

- ResearchGate, Flame Retardancy of Cellulose-based Filter Paper

- Industry forum: LinkedIn Filter Media Professionals

Post time: Aug-02-2025