Filters Accessories for Real-World Production: Notes From the Floor

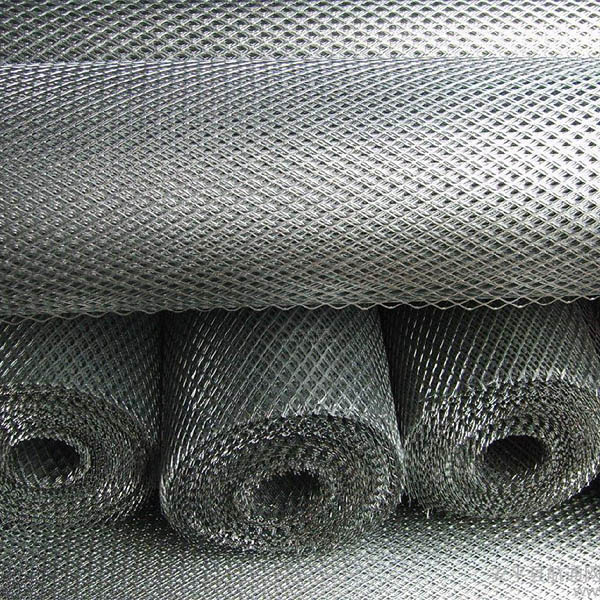

If you build or maintain filters, you already know the bottleneck is rarely the media; it’s the parts around it. That’s why I spent time with a Hebei supplier offering filters accessories for one-stop procurement—PU glue, plastic molds for PU filters, end caps, gaskets, adhesives, frames, and metal wire mesh. To be honest, it’s the kit you reach for when deadlines are ugly and tolerances are unforgiving.

What’s trending

- Faster pot-life PU systems for high-throughput automotive lines.

- Low-VOC adhesives and RoHS/REACH compliant elastomers for HVAC and consumer devices.

- Modular end caps and frames that cut tooling time (surprisingly big time-saver).

- Wire mesh with tighter flatness tolerances for robotic pleater compatibility.

Core specs at a glance

Below is a snapshot I jotted down from recent builds. Real-world use may vary (shop humidity matters more than we admit).

| Accessory | Material/Option | Key Spec (≈) | Notes |

|---|---|---|---|

| PU Glue | 2K PU, fast/standard cure | Viscosity 2–6 Pa·s; Pot life 3–12 min; Tg up to 70°C | Peel ≥ 3 N/mm (ASTM D903) |

| End Caps | Galv. steel, Al, Nylon | Salt spray ≥ 120 h (ASTM B117) | Custom emboss, vent holes |

| Gaskets | NBR, EPDM, Silicone | Shore A 35–70; -40~200°C | Compression set per ASTM D395 |

| Filter Frames | Steel, Al, ABS, PP | Flatness ≤ 0.3 mm/300 mm | Food-grade options (21 CFR) |

| Metal Wire Mesh | SS304/316, Galv. | 10–200 mesh; ASTM E2016 | Annealed for pleatability |

Process flow, testing, and service life

- Materials: certified PU systems, elastomers (NBR/EPDM), SS mesh, coated steels.

- Methods: die-cutting, injection molding, CNC stamping, adhesive dispensing (±0.2 mm bead), oven cure.

- Testing: ISO 16890/ASHRAE 52.2 for assemblies; ISO 16889 for hydraulic elements; fabrication integrity per ISO 2942; fluid compatibility ISO 2943.

- Service life: HVAC gaskets ≈ 1–3 years; industrial end caps 8k–20k operating hours; it depends on temp and media loading.

- Industries: automotive intake, dust collection, HVAC, compressor lube, cleanrooms, paint booths.

Vendor comparison (quick view)

| Vendor | MOQ (≈) | Lead Time | Certs | Customization |

|---|---|---|---|---|

| Anya Filter Media (Hebei) | 500–1,000 pcs | 10–20 days | ISO 9001, RoHS, REACH | Molds, logos, bespoke sizes |

| Market Vendor A | 1,500+ | 20–30 days | ISO 9001 | Limited mold library |

| Market Vendor B | 1,000 | 15–25 days | ISO 9001, RoHS | Some customization |

Applications and advantages

Automotive and off-road filters need end caps that won’t delaminate under thermal cycling; HVAC prefers silicone gaskets for low compression set; dust collectors want SS316 mesh for corrosion. The upside of filters accessories sourced together: fewer supplier handoffs, tighter tolerance stack-ups, and simpler QA paperwork. Many customers say assembly scrap fell by 2–3% after switching to single-source caps + adhesives.

Compliance, data, and customization

- Compliance: ISO 9001; RoHS; REACH; optional FDA 21 CFR contact-grade components.

- Test data (typical): PU-to-paper peel 3–5 N/mm; shear 8–12 MPa (ASTM D1002); frames pass 120–240 h B117; HVAC assemblies qualified to ISO 16890; hydraulic elements validated per ISO 16889 multipass.

- Customization: shore hardness, pot life tuning, color coding, embossed branding, private molds.

Two quick case notes

Case 1 — HVAC OEM: swapped to low-VOC PU + silicone gasket; pressure drop unchanged, leakage cut to 0.1% @ 600 Pa, line speed +12% due to faster cure.

Case 2 — Mining dust collector: galvanized caps replaced with Al; weight -18%, corrosion complaints near zero after rainy season; service interval extended from 6 to 9 months.

Origin and availability

Manufactured in No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China. Freight options are flexible; I guess most readers will care that cartons are barcoded and molds can be serialized—handy for audits. One-stop filters accessories supply saves you from juggling four POs for a single filter SKU.

Citations

- ISO 16890 Air filters for general ventilation — iso.org

- ASHRAE Standard 52.2 — ashrae.org

- ISO 16889 Hydraulic fluid power filters — Multi-pass test — iso.org

- ISO 2942/2943 Filter integrity & fluid compatibility — iso.org

- ASTM D903 Peel resistance; ASTM D1002 Lap shear; ASTM B117 Salt spray — astm.org

- REACH Regulation (EC) No 1907/2006 — echa.europa.eu

- RoHS Directive 2011/65/EU — eur-lex.europa.eu

- ISO 9001 Quality management systems — iso.org

Post time: Oct-08-2025