Industry Trends and Market Dynamics in Filter Manufacturing

The global demand for high-performance filtration solutions is experiencing robust growth, driven by escalating environmental regulations, increased awareness of air and water quality, and the expansion of industrial sectors. Manufacturers are constantly seeking advanced equipment to meet these evolving requirements, making the filter making machine a critical asset in modern production lines. Market analysis indicates a Compound Annual Growth Rate (CAGR) of over 6% for the global industrial filters market, projecting a valuation exceeding $40 billion by 2027. This growth is predominantly fueled by sectors such as HVAC, automotive, pharmaceutical, food and beverage, and petrochemical industries, all of which rely heavily on efficient filtration for operational integrity and product purity.

Technological advancements are steering the industry towards greater automation, precision, and material efficiency. Modern filter making machine systems are integrating AI-driven controls, advanced robotics, and enhanced sensor technologies to optimize production speed, minimize material waste, and ensure consistent product quality. The shift towards sustainable manufacturing also emphasizes machines capable of processing eco-friendly filter media and optimizing energy consumption during the production process.

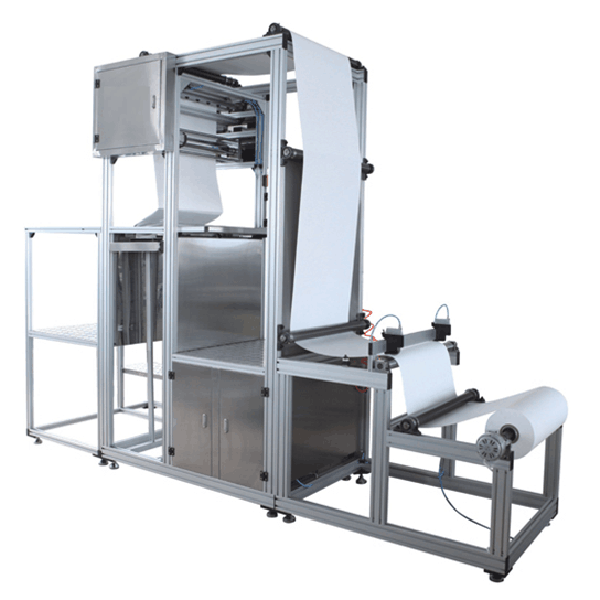

Fig 1: Advanced Pleating Technology in a Modern Filter Making Machine.

The Advanced Manufacturing Process of Filtration Media

The production of high-quality filters, whether it’s an air filter manufacturing machine or a liquid filter variant, is a multi-stage process requiring precision engineering and specialized machinery. This intricate process ensures the filters meet stringent industry standards for efficiency, durability, and service life.

Key Materials Employed:

- Non-woven Fabrics: Primarily melt-blown and spun-bond polypropylene or polyester, offering excellent depth filtration and dust-holding capacity. These are crucial for producing high-efficiency particulate air (HEPA) filters and automotive cabin filters.

- Fiberglass Media: Known for its high efficiency and resistance to high temperatures, commonly used in industrial HVAC and specialized process filtration.

- Activated Carbon: Integrated into filter media for odor absorption and removal of volatile organic compounds (VOCs).

- Synthetic Blends: Engineered for specific applications requiring enhanced strength, chemical resistance, or hydrophobicity.

- Metal Mesh: Stainless steel or aluminum mesh provides structural support and can act as a primary filtration layer for coarser particles, particularly in high-temperature or high-pressure environments.

Manufacturing Process Flow:

Step 1: Media Preparation & Unwinding

Filter media rolls are loaded onto the machine. Automated tension control systems ensure smooth and consistent unwinding, preventing distortion or stretching of delicate media. Material defect detection systems are often integrated.

Step 2: Pleating/Forming

This critical stage involves forming the filter media into a pleated structure. Techniques include knife pleating (for deeper, V-shaped pleats) and rotary pleating (for mini-pleats or hot-melt separation). Precision control ensures uniform pleat height and spacing, crucial for filtration efficiency and dust holding capacity.

Step 3: Media Separation & Bonding

For mini-pleat filters, hot-melt adhesive beads or threads are applied between pleats to maintain uniform spacing and prevent pleat collapse. Ultrasonic welding or heat sealing can also be used for certain synthetic media to create robust bonds without adhesives.

Step 4: Frame Assembly & Sealing

The pleated media pack is then inserted into a frame, which can be constructed from galvanized steel, aluminum, or plastic (often injection-molded). The media is securely sealed to the frame using sealants like polyurethane foam, silicone, or epoxy resins, ensuring no bypass leakage.

Step 5: Gasket Application & Finishing

Gaskets (e.g., neoprene, EPDM) are applied to the filter frame to ensure a tight seal within the filter housing. Depending on the filter type, additional components like face guards or bracing wires may be added for structural integrity.

Step 6: Quality Control & Testing

Each finished filter undergoes rigorous testing, including pressure drop testing (to measure air resistance), leak testing (e.g., DOP or PAO scan test for HEPA filters), and visual inspection. Performance validation against standards like ISO 16890, EN 779, or ASHRAE 52.2 is crucial.

The service life of a filter, directly impacting operational efficiency and maintenance costs, is a critical performance metric. It is significantly influenced by the quality of the raw materials, the precision of the manufacturing process carried out by the air filter making machine, and the specific application environment. Optimally manufactured filters exhibit extended service lives, reducing downtime and replacement frequency.

Target industries benefiting from these highly specialized machines include:

- Petrochemical: Filters for gas processing, catalyst protection, and solvent recovery.

- Metallurgy: Dust collection and fume extraction in foundries and smelting operations.

- Water Supply & Drainage: Production of media for industrial water treatment, municipal water purification, and wastewater management.

- HVAC & Cleanroom Technology: Manufacturing of HEPA, ULPA, and general ventilation filters for hospitals, data centers, and pharmaceutical production facilities.

- Automotive: Production of air, oil, fuel, and cabin filters for internal combustion engines and electric vehicles.

Advantages in typical application scenarios include significant energy savings due to lower initial pressure drop and longer operational life, superior corrosion resistance achieved through robust material selection and sealing, and enhanced filtration efficiency leading to cleaner environments and processes.

Fig 2: Precision Pleating Section of a Filter Manufacturing Line.

Technical Specifications and Data Visualization

Modern filter making machine systems are engineered with advanced technical specifications to deliver unparalleled performance and versatility. These parameters are crucial for assessing the machine's capability to meet specific production demands and quality standards.

Typical Specifications of a Modern Filter Making Machine

| Parameter | Specification |

|---|---|

| Production Speed (Pleating) | Up to 50-80 meters/minute |

| Compatible Media Width | 300mm - 1200mm (adjustable) |

| Pleat Height Range | 10mm - 100mm (programmable) |

| Pleat Count Precision | ±0.5 pleats/inch |

| Power Consumption | 15 kW - 45 kW (depending on configuration) |

| Control System | Siemens/Allen-Bradley PLC with HMI touchscreen |

| Frame Material Compatibility | Galvanized steel, aluminum, various plastics |

| Adhesive System | Hot-melt adhesive dispensing, ultrasonic welding optional |

| Overall Dimensions (L x W x H) | ~8-15m x 2-3m x 2-2.5m |

| Operating Noise Level | ≤ 75 dB(A) |

These specifications highlight the advanced engineering required to achieve high throughput, precision, and adaptability across various filter types. The integration of sophisticated PLC systems allows for precise control over pleat geometry, adhesive application, and overall production flow, minimizing human error and maximizing output efficiency.

Fig 3: Control Panel and HMI for an Advanced Filter Manufacturing Machine.

Technical Advantages Driving Modern Filter Production

Investing in a state-of-the-art air filter manufacturing machine offers a multitude of technical advantages crucial for competitive market positioning and operational excellence.

- Unmatched Precision and Consistency: Advanced servo-driven systems ensure precise pleat formation, consistent pleat height, and accurate adhesive application, leading to filters with uniform filtration performance and extended service life.

- High Degree of Automation: From automated media unwinding and pleating to robotic handling and final assembly, automation significantly reduces labor costs, minimizes human error, and boosts production output.

- Enhanced Production Efficiency: High operating speeds and continuous production capabilities ensure substantial daily output, critical for meeting large-scale industrial demand and reducing per-unit manufacturing costs.

- Versatility in Filter Type Production: Modern machines can be rapidly reconfigured to produce a wide array of filter types, including panel filters, V-bank filters, cylindrical filters, and specialized HEPA/ULPA filters, accommodating diverse market needs.

- Waste Reduction and Material Optimization: Optimized material utilization algorithms and precise cutting mechanisms minimize scrap material, contributing to cost savings and environmental sustainability.

- Integrated Quality Control: Many systems feature in-line inspection systems, such as optical sensors for pleat integrity or pressure sensors for flow resistance, providing real-time quality assurance and reducing post-production rejection rates.

- Robust Build and Durability: Constructed from high-grade steel alloys and precision-machined components, these machines are designed for continuous heavy-duty operation with minimal wear, ensuring a long operational lifespan and high ROI.

These advantages collectively contribute to higher product quality, lower operational expenses, and greater manufacturing flexibility, enabling companies to respond effectively to market demands for advanced filtration solutions.

Broad Application Scenarios Across Industries

The versatility of an advanced filter making machine allows it to serve a vast array of critical applications across diverse industrial landscapes. The ability to customize filter media, pleating density, and frame designs means these machines are indispensable for manufacturers catering to specialized demands.

- HVAC and Air Purification: Production of high-efficiency filters (MERV 13 to HEPA H14) for commercial buildings, hospitals, cleanrooms, and residential HVAC systems, ensuring superior indoor air quality and pathogen control.

- Automotive Industry: Manufacturing of engine air filters, cabin air filters, oil filters, and fuel filters, essential for vehicle performance, fuel efficiency, and passenger health.

- Industrial Dust Collection: Production of cartridge filters, bag filters, and panel filters used in industrial processes such as woodworking, metalworking, mining, and cement manufacturing to capture particulate matter and ensure worker safety.

- Pharmaceutical and Biotechnology: Manufacturing of ultra-pure air filters for sterile environments, vent filters for bioreactors, and liquid filters for media and product clarification, meeting stringent regulatory requirements (e.g., FDA).

- Food and Beverage Processing: Production of filters for water purification, steam filtration, compressed air filtration, and ingredient processing, ensuring product safety and quality.

- Water and Wastewater Treatment: Fabrication of membrane filters, cartridge filters, and depth filters for municipal water treatment plants, industrial process water, and wastewater effluent polishing.

- Oil and Gas: Manufacturing of process filters, separator elements, and coalescers for gas processing, hydraulic systems, and lubricant purification in upstream and downstream operations.

In each scenario, the precisely manufactured filters contribute significantly to operational efficiency, regulatory compliance, equipment protection, and environmental stewardship. The agility of modern filter making machine systems allows for rapid shifts in production to meet the unique demands of these diverse markets.

Fig 4: Application of Filters Produced by the Machine in Industrial Settings.

Vendor Comparison and Strategic Selection

Selecting the right vendor for a filter making machine is a strategic decision that impacts long-term operational efficiency, product quality, and return on investment. Key factors to consider include technological innovation, after-sales support, customization capabilities, and proven industry reputation.

Comparative Analysis of Filter Making Machine Vendors

| Feature/Vendor | Vendor A (Leading Innovator) | Vendor B (Cost-Effective Solution) | Vendor C (Specialized Niche) |

|---|---|---|---|

| Automation Level | Full Automation (Robotic integration, AI-driven) | Semi-Automated (Modular upgrades available) | High Automation (Focus on specific filter types) |

| Machine Type Focus | Versatile (HEPA, Panel, V-bank) | Standard Filters (Panel, Bag) | Mini-Pleat & Cylindrical Filters |

| After-Sales Support | Global network, 24/7 remote diagnostics, on-site | Regional support, standard hours, limited on-site | Specialized technicians, dedicated project support |

| Customization Options | Extensive (Tailored to specific production needs) | Moderate (Standard modules) | High (Deep integration for niche products) |

| Certifications & Standards | ISO 9001, CE, TUV, OSHA compliant | ISO 9001, CE | ISO 9001, Industry-specific certifications |

| Average Lead Time | 16-24 weeks | 10-18 weeks | 18-28 weeks (for specialized builds) |

Prospective buyers should conduct thorough due diligence, assessing not only the initial cost but also the total cost of ownership, including maintenance, spare parts availability, and the potential for future upgrades. A vendor with a robust R&D pipeline and a history of successful installations demonstrates greater long-term value.

Tailored Solutions: Customization and Flexibility

Recognizing that no two manufacturing operations are identical, leading air filter making machine providers offer comprehensive customized solutions. This flexibility ensures that the machinery integrates seamlessly into existing production lines and meets highly specific operational requirements.

- Modular Design: Many advanced machines are built with modular components, allowing clients to select specific pleating modules, adhesive application systems, or cutting mechanisms to suit their product portfolio.

- Software Customization: PLC and HMI interfaces can be programmed to include custom recipes for different filter types, integrate with factory MES (Manufacturing Execution Systems), and provide tailored performance analytics.

- Material Handling Integration: Solutions can be designed to interface with existing material unwinding, feeding, and finished product packaging systems, creating a fully automated, end-to-end production line.

- Capacity Scaling: Machines can be configured for varying production volumes, from pilot-scale operations to high-volume manufacturing, with options for future capacity upgrades.

- Specialized Filter Media Processing: Custom modules can be developed to handle challenging media, such as ultra-thin membranes, highly rigid metal meshes, or multi-layered composite materials, required for niche applications.

This adaptability is crucial for manufacturers seeking to innovate and capture new market segments without requiring entirely new capital investments. A strong partnership with a vendor offering robust customization ensures a future-proof investment.

Fig 5: Example of a Custom-Built Module for Unique Filter Media Handling.

Application Case Studies and Customer Success

Real-world application case studies demonstrate the tangible benefits derived from deploying advanced filter making machine technology. These examples underscore the impact on efficiency, quality, and profitability.

Case Study 1: Automotive Filter Manufacturer - Throughput & Precision Upgrade

A major automotive filter producer faced challenges with inconsistent pleat spacing and limited production capacity using outdated machinery. By integrating a new generation air filter making machine with servo-driven pleating and automated hot-melt separation, they achieved a 40% increase in daily output. Pleat height variation was reduced by 75%, leading to superior filter performance and a significant reduction in quality control rejections. Customer feedback highlighted the consistent quality of the finished filters, improving brand reputation and market share.

Case Study 2: HVAC Filter Specialist - Expanding Product Portfolio

An HVAC filter manufacturer aimed to diversify into high-efficiency HEPA and ULPA filters for cleanroom applications but lacked the precise pleating technology. They invested in a specialized mini-pleat filter making machine, equipped with a high-precision rotary pleater and automated adhesive bead application. This enabled them to produce filters meeting ISO 29463 (HEPA/ULPA) standards, opening new revenue streams in the pharmaceutical and microelectronics sectors. The machine's rapid changeover capabilities also allowed them to maintain efficient production of their existing MERV-rated filters.

Fig 6: Final Assembly Line for Filters Produced by High-Volume Machinery.

Frequently Asked Questions (FAQ)

Q1: What types of filter media can your filter making machine process?

A1: Our machines are designed to process a wide range of filter media, including various non-woven fabrics (melt-blown, spun-bond, synthetic blends), fiberglass, activated carbon composites, and fine metal meshes. Custom modules can be integrated for specialized media.

Q2: What is the typical lead time for a new filter making machine?

A2: Lead times typically range from 12 to 24 weeks, depending on the machine's complexity, level of customization, and current production schedule. We provide a precise timeline upon order confirmation.

Q3: What kind of warranty and after-sales support do you offer?

A3: We provide a standard 12-month warranty on all mechanical and electrical components, with extended warranty options available. Our comprehensive after-sales support includes remote diagnostics, on-site technical assistance, spare parts availability, and operator training programs.

Q4: Can your machines produce filters that meet specific international standards like ISO 16890 or ASHRAE 52.2?

A4: Absolutely. Our machines are engineered to produce filters capable of meeting and exceeding international standards such as ISO 16890, EN 779, ASHRAE 52.2, and others. The precision of our manufacturing process ensures that the filter media is optimally utilized to achieve the required filtration efficiency and pressure drop characteristics.

Commitment to Quality, Service, and Trust

Our dedication to engineering excellence is underpinned by stringent quality control and adherence to international standards. Our manufacturing facilities are ISO 9001:2015 certified, guaranteeing robust quality management systems throughout the design, production, and testing phases of every filter making machine. Furthermore, our products comply with CE directives, ensuring they meet European health, safety, and environmental protection standards.

We stand behind our products with comprehensive warranty commitments and a proactive customer support framework. Our technical support teams are available globally, offering remote troubleshooting, on-site assistance, and preventive maintenance programs to ensure maximum uptime and operational efficiency for your investment. We also maintain a readily available inventory of critical spare parts, minimizing potential downtime and securing your production continuity.

Partnering with us means gaining access to decades of industry experience, a proven track record with leading global manufacturers, and a commitment to innovation that continually pushes the boundaries of filter production technology. Our long-standing relationships with key industry clients and our reputation for delivering reliable, high-performance solutions underscore our authoritativeness in the field.

Authoritative References

- International Organization for Standardization (ISO). ISO 16890:2016, Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM).

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ASHRAE Standard 52.2-2017, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- European Standard (EN). EN 779:2012, Particulate air filters for general ventilation – Determination of the filtration performance.

- MarketsandMarkets. Industrial Filters Market by Type (Air, Liquid), Filter Media (Activated Carbon, Fiberglass, Metal), Application (Manufacturing, Power Generation, Oil & Gas), and Region - Global Forecast to 2027.

Post time: Sep-13-2025