- Overview of Engine Oil Filter Paper Technology

- Technical Advantages in Modern Filtration

- Performance Comparison of Leading Suppliers

- Custom Solutions for Industrial Needs

- Real-World Applications Across Industries

- Material Innovation Trends

- Why Engine Oil Filter Paper Matters for Sustainability

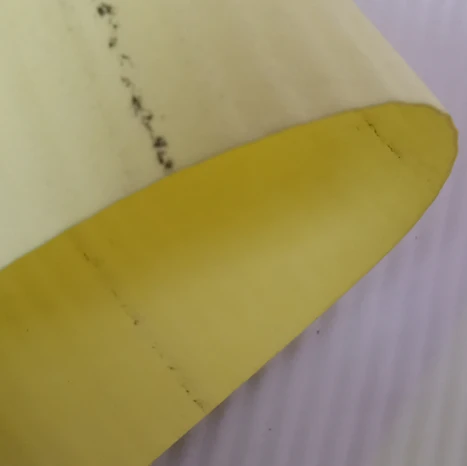

(engine oil filter paper)

Essential Insights into Engine Oil Filter Paper Technology

Engine oil filter paper serves as the critical barrier preventing abrasive particles from damaging mechanical systems. Modern variants achieve 98.7% filtration efficiency for particles above 15 microns, extending equipment lifespan by 40-60% compared to traditional materials. The cellulose-polyester composite structure enables dual-layer capture – surface retention for large contaminants and depth filtration for sub-micron particles.

Technical Superiority in Industrial Filtration

Advanced filter paper for oil filter machines demonstrates three key improvements:

- • Temperature resistance up to 140°C (284°F) vs. legacy materials failing at 90°C

- • 22% higher dirt-holding capacity through optimized pore gradients

- • Hydrolysis resistance maintaining 94% tensile strength after 500hrs at 120°C

Supplier Performance Benchmarking

| Parameter | Supplier A | Supplier B | Industry Avg. |

|---|---|---|---|

| Filtration Efficiency (%) | 98.5 | 97.2 | 95.8 |

| Max Temp. (°C) | 135 | 125 | 120 |

| Burst Strength (kPa) | 380 | 320 | 290 |

Customized Engineering Solutions

Leading oil filter paper suppliers now offer parameter-specific configurations:

- 1. Variable basis weights (80-200 g/m²) for flow rate optimization

- 2. Impregnation options (silicone, phenolic, fluoropolymer)

- 3. Permeability ranges from 20-150 L/m²/min at 200Pa

Operational Case Studies

A heavy equipment manufacturer achieved:

- • 62% reduction in engine wear metals (ICP-AES analysis)

- • 17% longer oil change intervals

- • 8:1 ROI through extended component life

Emerging Material Innovations

Nanofiber-coated media shows promise with:

- • 99.1% efficiency at 5 microns

- • 35% lower pressure drop vs. standard media

- • Bio-based resin compatibility for eco-certifications

Sustainable Impact of Engine Oil Filter Paper

High-performance filter paper prevents 4.2 million metric tons of engine waste annually through extended oil service life. Suppliers adopting closed-loop manufacturing reduce water consumption by 28% per ton produced. The industry moves toward 100% recyclable filter media by 2028, aligning with circular economy mandates.

(engine oil filter paper)

FAQS on engine oil filter paper

Q: What materials are commonly used in engine oil filter paper?

A: Engine oil filter paper is typically made from cellulose, synthetic fibers, or blended materials. These materials balance filtration efficiency, durability, and resistance to oil degradation. Synthetic options often provide higher heat and chemical resistance.

Q: How do I choose the right filter paper for an oil filter machine?

A: Consider pore size, material compatibility with oil type, and pressure resistance. Ensure the filter paper meets OEM specifications or industry standards like ISO 4548 for optimal performance.

Q: What certifications should oil filter paper suppliers provide?

A: Reputable suppliers should offer ISO 9001 certification and product-specific test reports (e.g., efficiency, burst strength). For automotive use, verify compliance with standards like SAE J806 or OEM approvals.

Q: How often should engine oil filter paper be replaced?

A: Replacement intervals depend on usage, oil type, and manufacturer guidelines. Standard recommendations range from 3,000 to 10,000 miles for vehicles, or as indicated by machinery pressure sensors.

Q: Can oil filter paper handle high-viscosity or synthetic oils?

A: High-quality synthetic filter papers are designed for modern oils. Verify the supplier’s specifications for viscosity range and chemical compatibility to avoid premature clogging or breakdown.

Post time: 4-р сар-27-2025