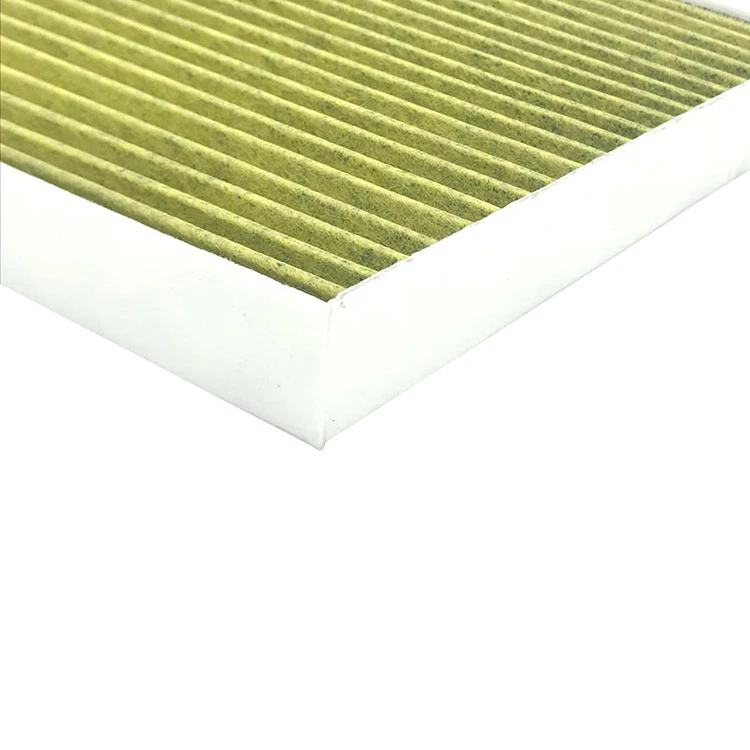

When it comes to industrial applications, having effective dust collector filter media is crucial for ensuring clean air and maintaining equipment efficiency. Dust collector filter media is the core component of dust collection systems, designed to capture particulate matter and prevent it from entering the environment. These filters are made from durable materials, including polyester filaments and various other fibers, to provide the necessary filtration performance for different industries.

The dust collector filter media works by trapping particles as air passes through the filter material. The media's porous structure allows air to flow through while effectively capturing dust, debris, and even fine particulates. Whether you're running a manufacturing plant, an automobile facility, or any other industrial operation, selecting the right dust collector filter media ensures optimal air quality and system efficiency.

An ideal dust collector filter media should offer high air permeability to allow for easy airflow, while still being dense enough to capture a wide range of particles. It should also be resistant to wear and tear, offering long-lasting performance even under harsh conditions. With the increasing awareness of air quality and environmental standards, the demand for superior dust collector filter media has grown tremendously.

The Importance of Dust Collector Filter Cloth

In the world of dust filtration, dust collector filter cloth is an indispensable material that plays a crucial role in maintaining the performance of dust collection systems. Made from various synthetic materials, including polyester and other high-strength fibers, dust collector filter cloth offers a durable and effective solution for capturing dust and airborne particles.

The strength and durability of dust collector filter cloth ensure that it can withstand the harsh environments of industrial operations. Whether you’re dealing with high temperatures, abrasive materials, or high-velocity airflows, this filter cloth is designed to provide reliable performance over time. It features excellent tensile strength, ensuring that it won’t tear or stretch under pressure. The dust collector filter cloth is also engineered to be corrosion-resistant, making it suitable for even the toughest applications, such as chemical processing plants or metalworking environments.

One of the standout features of dust collector filter cloth is its versatility. The material can be customized to meet specific needs by adjusting properties like thickness, porosity, and resistance to chemicals. As businesses face increasing demands to meet environmental regulations, the right dust collector filter cloth ensures compliance and helps improve air quality in the surrounding areas.

Advantages of Dust Filter Material Roll

Another valuable option in the dust filtration industry is dust filter material roll. This product offers several advantages that make it ideal for large-scale filtration systems. The dust filter material roll comes in continuous lengths, which makes it easier to customize the filter size based on the specific requirements of your dust collection system.

Dust filter material roll is often made from high-quality fabrics like polyester or fiberglass, which can be treated with special coatings such as PTFE (polytetrafluoroethylene) or aluminized layers for added durability. These treatments enhance the material’s resistance to high temperatures, moisture, and chemicals, ensuring that it maintains its performance even in extreme conditions.

The use of dust filter material roll is particularly beneficial in industries that require large quantities of filter media, such as cement manufacturing, mining, or power generation. It allows for easy and efficient replacement of filter bags and pleated filter cartridges, ensuring that filtration systems continue to perform at their best. Furthermore, the roll format allows for flexible cutting and installation, making it easier to fit various types of filtration equipment and configurations.

How Filter Cloth for Dust Collectors Works

Understanding how filter cloth for dust collectors works is essential for selecting the right type of media for your filtration needs. Filter cloth for dust collectors is designed to capture airborne dust particles as they pass through the cloth. The material’s structure is made of fine, tightly woven fibers that form a barrier against particulate matter.

The process begins when air enters the dust collection system and passes through the filter cloth for dust collectors. As the air moves through the material, larger particles are trapped on the surface, while smaller particles penetrate the cloth and are captured within the fibers. Over time, the captured dust forms a dust cake on the filter surface, improving filtration efficiency by capturing even finer particles.

This self-cleaning process ensures that filter cloth for dust collectors remains efficient even as it collects more dust. When the dust cake becomes too thick, the system can automatically clean the filter through a process known as pulse jet cleaning. This helps maintain the filter’s performance and prevents clogging, which can reduce airflow and cause system failure.

The primary benefits of filter cloth for dust collectors include improved air quality, increased filtration efficiency, and reduced maintenance costs. Whether you’re working with hazardous dust or simply trying to meet environmental standards, the right filter cloth for dust collectors ensures that your filtration system remains effective and reliable over time.

Selecting the Right Dust Collector Filter Media for Your Needs

Choosing the right dust collector filter media for your application is crucial for achieving optimal filtration performance. The first factor to consider is the type of dust or particles your system needs to capture. Some industries, like food processing or pharmaceuticals, require filters with extremely fine filtration capabilities, while others may only need to capture larger particles.

Another important factor is the environment in which the filter will be used. High temperatures, chemical exposure, or high-pressure conditions may require specialized materials, such as dust collector filter cloth with additional treatments like flame retardancy or anti-static properties. The right material will ensure that the filter can handle these conditions without compromising its efficiency.

Additionally, you should also consider the air permeability and tensile strength of the dust collector filter media. High air permeability ensures that the filter allows air to flow freely through the system, while tensile strength ensures that the media won’t tear or stretch under pressure. By selecting a dust collector filter media with the right balance of these properties, you can achieve both high filtration efficiency and long-lasting performance.

Dust Collector Filter Media FAQs

What is dust collector filter media made of?

Dust collector filter media is typically made from synthetic fibers, such as polyester or fiberglass, that are woven or spun to create a durable and efficient filter. Some types may also have additional coatings like PTFE or aluminized layers to enhance performance.

How do I know which dust collector filter cloth is right for my system?

The right dust collector filter cloth depends on the type of dust or particulate matter you need to filter, the environmental conditions (such as temperature and humidity), and the specific requirements of your filtration system.

What industries use dust filter material roll?

Dust filter material roll is commonly used in industries that require large-scale filtration systems, including cement manufacturing, mining, power generation, and chemical processing. It provides an efficient and customizable solution for replacing filter media in dust collectors.

How does filter cloth for dust collectors work?

Filter cloth for dust collectors works by trapping airborne dust particles as they pass through the material. It uses tightly woven fibers to capture particles, while the self-cleaning process ensures the filter continues to operate efficiently over time.

Why should I choose high-quality dust collector filter media?

High-quality dust collector filter media offers superior filtration efficiency, increased durability, and improved air quality. It can help your system maintain optimal performance, reduce maintenance costs, and ensure compliance with environmental regulations.

In today’s industrial world, clean air and efficient dust collection are crucial for both the health of your workers and the overall performance of your equipment. Investing in high-quality dust collector filter media ensures that you can meet the demands of your industry while maintaining optimal air quality. Browse our website for more information about our wide range of dust collector filter media products, and contact us today to find the right solution for your needs!

Post time: May-13-2025