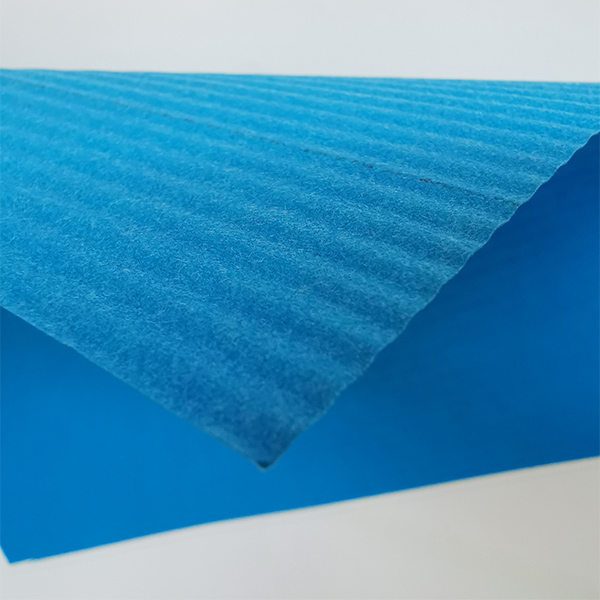

Průmyslový filtrační papír

Toto filtrační médium je vyrobeno z vysoce kvalitní dřevěné buničiny jako suroviny.

Vlastnosti produktu:

Dobrá propustnost vzduchu

Vysoká přesnost a účinnost filtrace

Vysoká kapacita zadržování prachu

Vysoká tuhost a odolnost proti roztržení

Vynikající pulzní reverzní čištění

Aplikace: Filtrační patrona plynové turbíny, sběrač prachu.

Popis produktu:

Materiál Celulóza + Syntetické/sklolaminátové vlákno

Akrylová pryskyřice

Základní Gramáž 110-150g/m2

Úroveň filtru: F7, F8, F9 (EN779:2012)

Poznámka: Další specifikace jsou k dispozici také podle požadavku zákazníka nebo vzorku.

Benefits of using high-efficiency industrial filter paper

High-efficiency industrial filter paper delivers superior performance in demanding filtration applications by effectively removing fine contaminants while maintaining optimal flow rates. Its advanced material composition, often incorporating synthetic fibers or resin treatments, ensures durability in high-pressure, high-temperature, and chemically aggressive environments. This results in extended service life and reduced maintenance costs. The enhanced filtration efficiency protects sensitive equipment from particulate damage, improving operational reliability and product quality in industries such as pharmaceuticals, food processing, and chemical manufacturing. Additionally, high-efficiency filter paper minimizes waste by maximizing contaminant retention, contributing to sustainable operations. Its ability to handle challenging conditions while maintaining consistent performance makes it a cost-effective solution for industries where filtration precision is critical.

High-Performance Filter Media for Gas Turbines and Dust Collectors

This advanced filter media is crafted from premium wood pulp, ensuring superior quality and reliability for demanding filtration applications. Designed to deliver exceptional performance, it combines excellent air permeability with high filtration precision, making it ideal for gas turbines and dust collectors where efficiency and durability are critical.The media features a robust blend of cellulose and synthetic/fiberlic fiber, reinforced with acrylic resin, providing high stiffness and burst resistance. With a basic weight ranging from 110 to 150g/m², it achieves filtration levels of F7, F8, and F9 (EN779:2012), ensuring fine particle capture and extended service life. Its high dust-holding capacity reduces maintenance frequency, while its outstanding pulse reverse cleanup performance enhances operational efficiency.

Micron ratings and porosity in industrial filter papers

Micron ratings and porosity are key factors determining the performance of industrial filter papers. The micron rating indicates the size of particles the filter can capture, with lower numbers (e.g., 1-10 microns) providing finer filtration for sensitive applications. Porosity, or the density of the fiber matrix, affects both filtration efficiency and flow rate—higher porosity allows faster flow but may compromise particle retention. Manufacturers balance these properties based on application needs; for example, a fuel filter requires tight micron control to protect engines, while a pre-filter may use a more open structure to handle high debris loads. Advanced industrial filter papers often feature gradient porosity or layered designs to optimize dirt-holding capacity without sacrificing flow. Understanding these parameters ensures proper filter selection for maximum efficiency and system longevity.