China Supplier Gap Filling Spray PU Foam Adhesive

carry on to improve, to ensure merchandise quality in line with market and shopper standard prerequisites. Our firm has a high quality assurance program are actually established for China Supplier Gap Filling Spray PU Foam Adhesive, We warmly welcome close friends from all walks of daily life to seek mutual cooperation and build a more excellent and splendid tomorrow.

carry on to improve, to ensure merchandise quality in line with market and shopper standard prerequisites. Our firm has a high quality assurance program are actually established for China Spray PU Foam and Spray Adhesive, Be sure to feel cost-free to send us your specifications and we will respond for you asap. We have got a specialist engineering team to serve for the every single detailed needs. Free samples may be sent for you personally personally to know far more facts. So that you can meet your desires, you should seriously feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Instructions:

1. Material-A should stirred evenly with plastic hand electric drill, material-B can shake, before used.

2. Open the electrocaloric plate temperature to 40-50 degrees, in winter material-A and material-B with a small container to preheat.

3. Wipe the mould with release agent

4. According to the local environment, such as the humidity in the air, workshop environment.

5. material-A and material-B are mixed at the mixture ratio of 100:40 ratio, then add 40% talcum powder(heavy calcium powder)(100:40:50±5), with 2800 rev / min motor to mix, mixing time determined by the amount of adhesive, per 100g of adhesive is approximately 7-10 seconds .

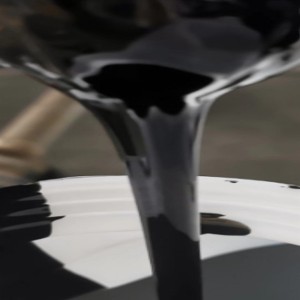

6. Pour the Mixed liquid into mould, then put the paper element and give a little pressure on it. 8-15 minutes later you can bring the mould down